Other Options

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam elementum, turpis et egestas mattis, massa tellus commodo purus, ac fringilla dolor dolor eu nisi. Aliquam et finibus urna. In imperdiet efficitur ornare. Pellentesque quis eleifend tortor, at dapibus arcu. Nullam neque felis, luctus nec pulvinar non, varius vitae turpis.

Cranes

P.D.Stevens have had a long proven history in the supply of truck mounted cranes ranging from the small hydraulic lifts often found in the 3.5tonne sector through to the larger crane types found on 18 and 26 tonne rigids.

Working hand in hand with the crane manufacturers, we have first hand experience in working with the likes of Hiab, Atlas, Palfinger, HMF and Penny to name a few. The larger cranes fitted to HGV products tend to go directly to the crane manufacturer first and then onto ourselves however the active dialogue we have with both the crane provider and the end user ensures that when a vehicle arrives with us, all of the vitally important and necessary areas such as positioning of ancillaries etc have all been agreed before the build goes ahead, thus allowing a seamless transition between the stages of build.

Driver Safety

Building a truck body may indeed to the uninitiated, appear to be a purely engineering led project however with the increase in Operative safety, our designs have been carefully honed and altered to ensure that every body we build has at its very heart, driver and operative safety in mind, whether they be next to or on the vehicle body itself.

We have worked tirelessly with end users in developing new step arrangements for example that allow access and egress of the vehicle body safely and quickly, ensuring that suitable hand and foot contact is available during the operation and then once on the body, to ensure that our own design safety rail arrangement now required for working at height, is both strong and easy to use within the day to day operation.

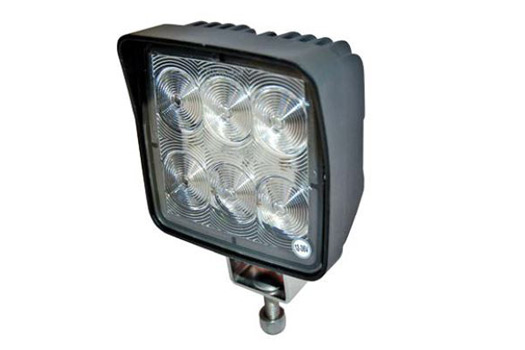

In addition to body steps and Working at Height safety systems, P.D.Stevens have extensive experience in the development of other driver safety devices, whether these be in the areas of body storage, design of security systems, integrated lashing eyes and extra electrical lighting systems that ensure your operatives are at all times, come rain or shine, given the best working environment when working out on site.

- Working at Height Systems

- Ramps

- 3 Point Contact Systems

Electrical

We have our own highly trained electrical technicians on site who not only create the most appropriate electrical circuits for the safe installation and working of the vast array of different electrical products from the latest LED lighting systems including beacons, strobes, internal flush lighting systems, reverse cameras and warning devices, additional spot lights, hand wash systems and so on.

- DVS compliant Camera systems with GPS

- Reversing systems

- Banksman underbody lighting

- Axtec on board weighing systems

Taillifts

We are experts in the integration within our body design of a wide range of taillifts whether they be Column, Cantilever or Tuck Away, as well as internal taillifts on the smaller LCV products too.

We are approved and authorised by major producers, like DEL and our fitting technicians are all trained and have completed manufacturers’ courses.

We source our taillifts from a wide range of suppliers including DEL, Racliffe Palfinger, Anteo, Dhollandia and Ricon to name a few and ensure that the design, complete with its safety features, form a integrated element of the rear of the vehicle by means of ensuring the correct use of rear hinge designs and bespoke rear frames that ensure a flush finish.

We can also supply and fit Tuck Away lifts to trailers for those operations that require such a design.

Keeping you vehicles moving is our priority and we focus on ensuring that our installations are of the highest quality thus creating high levels of reliability and safety.

We provide thorough statutory testing and certification including weight testing should you require.

- Column

- Cantelever

- Tuckaway

- Slider